This structure, which probably dates to the 1790s, was situated near the dairy barn complex so that raw milk could be easily brought for processing. The production of butter and cheese was the work of Shaker Sisters, who also milked the community’s herd. Dairy products were one of the leading commodities made by the Hancock Shakers from the earliest days of the community into the twentieth century.

This structure, which probably dates to the 1790s, was situated near the dairy barn complex so that raw milk could be easily brought for processing. The production of butter and cheese was the work of Shaker Sisters, who also milked the community’s herd. Dairy products were one of the leading commodities made by the Hancock Shakers from the earliest days of the community into the twentieth century.

The Dairy is situated over a natural spring that supplies cold water to a stone basin where milk products were set to cool. Butter was hand churned by the Sisters until June of 1894, when Sister Fidella Estabrook reported to The Manifesto: “Last year an aqueduct was placed in the dairy, by means of which water is now obtained for running the churn.”

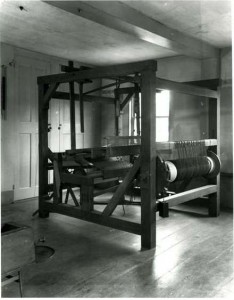

Hand loom, Church Family, Hancock, Massachusetts. Photo by Noel Vicentini, 1936, for the Federal Art Project of the WPA.

The second floor of the Dairy was added sometime after 1820 and was used as a weave loft. The Sisters wove cloth for clothes, wove rugs, and made bonnets. The constant demand for fabric needed by the ever growing family kept the shuttles flying. Hand weaving was practiced on a large scale until the late 1840s, when the mill at the North Family was constructed. By the mid-1860s the Shakers were purchasing most of their cloth from local mills that wove it to their specifications. By 1920 most Hancock community members had stopped wearing traditional Shaker clothing, and either purchased plain dresses from commercial outlets, or sewed for themselves.

As the industrial activities of the sisters became more complex, other structures were raised to meet the specialized needs of both brethren and sisters, such as clothier shops, seed shops, and nurse shops. Other shops were built devoted solely to the occupations of the female line such as the packaging of medicines, drying of sweet corn, and the manufacture of sewing notions and boxes.